In overhead transmission line either HVAC or HVDC, the grounding has very crucial importance due to various reasons which have been listed down in details.

Any transmission line at the beginning stage of its construction, the ground work is implemented. As the tower having four legs hence in all four legs the grounding connections is required. In this article, I have detailed the grounding requirements and other important parameters that is noted down during making earthing connections before the all four legs of are concreted. It should be noted that the things in this article is mostly in reference of 500KV HVDC. So the grounding requirements may change as per the project requirement.

Purpose of Transmission Line Grounding:

-

To safeguard a person from electric shock by ensuring that, under fault conditions, all surfaces including those of metallic equipment and the ground with which he is in simultaneous contact, remain at a safe relative potentials.

-

To dissipate both voltages and currents under fault conditions without exceeding predictable limits or adversely affecting continuity of service.

-

To provide a path to dissipate surges induced by lightning or switching surges and to provide a path to ground from the overhead ground wire.

-

To reduce the possibility of static discharge caused by natural electric disturbances in the atmosphere.

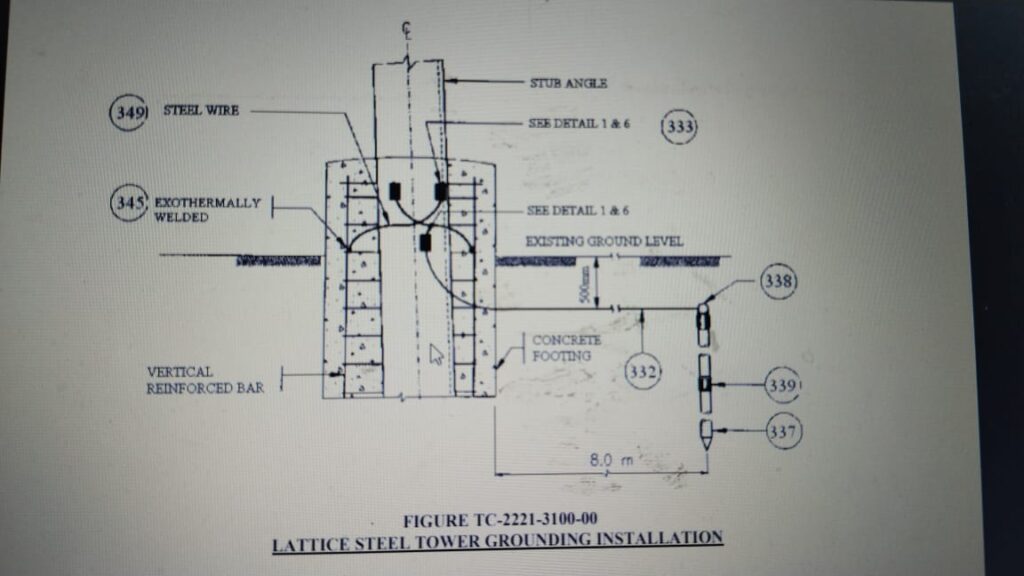

In the case of Steel Lattice Structures, below are the important points to be noted while grounding: Taking figure 2 in reference

1) Latticed steel structure shall be grounded on its two opposite legs by means of counterpoise and two Thermite coupled ground rods extended outward at 180 deg or in line with two opposite legs.

2) All grounding materials shall be copper clad steel and shall be free of damage.

3) Copper Clad steel Ground Rod shall have 19.05 mm actual diameter and minimum of 3m in length and another shall have 15.88 mm actual diameter with the same minimum length of 3m.

4) All bends in the grounding conductor shall have a bending radius equal to or greater than 75 mm.

5) The counterpoise shall be parallel to the transmission line and shall be buried 500mm below grade for normal ground.

6) During the process if rock surfaces are encountered, rock shall be cut at least 150mm deep then buried the counterpoise, also the counterpoise shall be buried a minimum depth of 1800 mm in dune areas.

7) Counterpoise shall be measured at least 8m from foundation footings to ground rod at two (2) opposite legs. (Refer Fig 1 right down)

8) Inhibiting compound shall be provided between Lug and Stub. Also, the grounding system connection at the reinforcement bar and and at the Ground Rod shall be exothermally welded, then coated with two coats of coal tar epoxy and mastic taped. (refer figure 2)